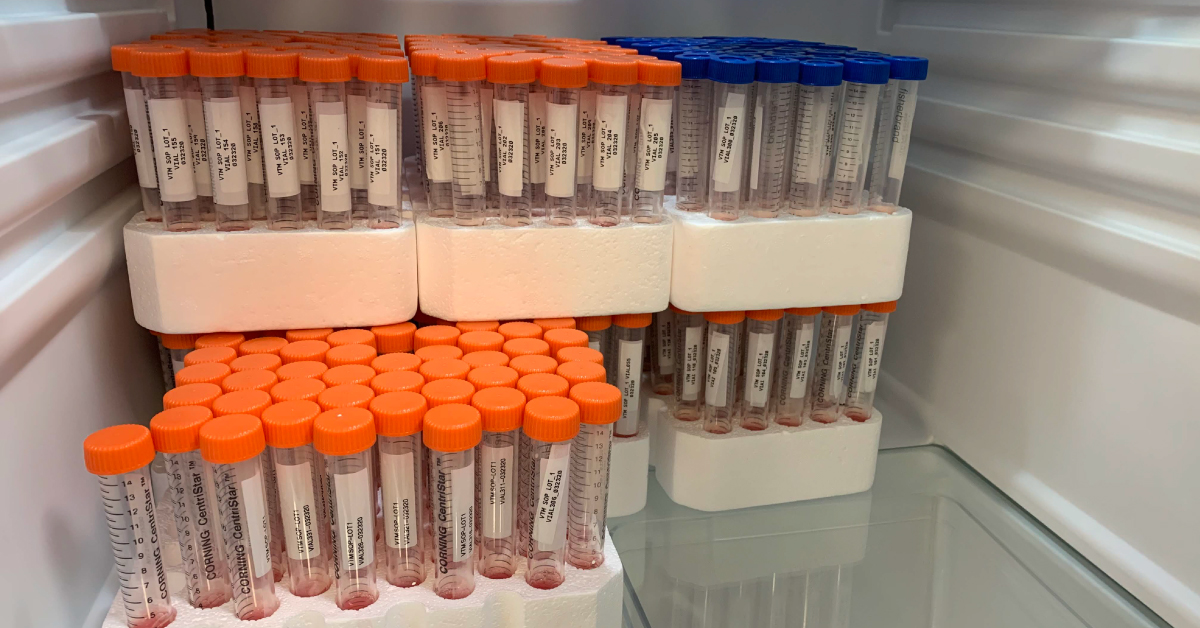

A challenge for the medical professionals across the country battling COVID-19 has been readily available testing components. In Amarillo, in particular, physicians faced a lack of commercially available viral transport media (VTM) testing vials. VTM is a sterile tube with 1mL or 3mL of cell culture media, that contains a broad-spectrum antibiotic and an antifungal agent. The VTM protects the virus samples obtained from nose or throat swabs. Because COVID-19 is particularly unstable, it’s important those samples don’t degrade in transit to processing facilities. Any changes could lead to incorrect testing results.

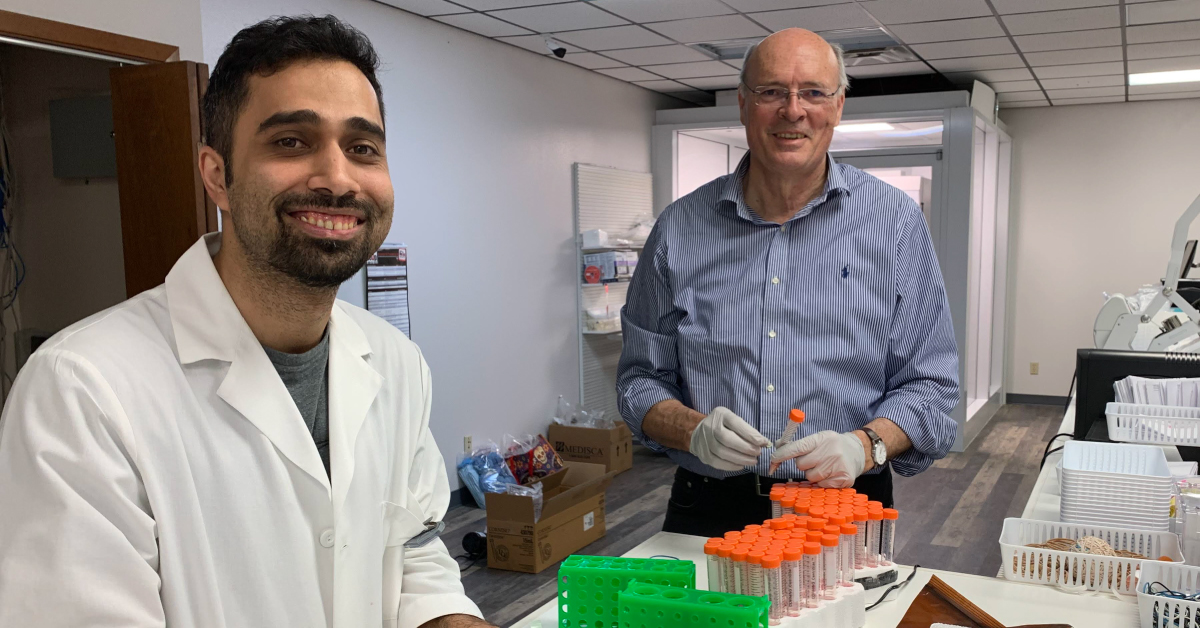

TTUHSC Associate Professor of Pediatrics Todd Bell, M.D., partnered with Eric MacLaughlin, Pharm.D., Chair of Pharmacy Practice, Mikala Conatser, Pharm.D., assistant professor, and Ulirich Bickel, Pharm.D., professor and associate dean of Sciences in the TTUHSC School of Pharmacy, to find a solution.

“While we didn’t have VTM in our labs, a literature search revealed that such VTM could be prepared in-house from materials that are readily available in many labs doing cell culture work,” Bickel said.

On March 22, the team produced an initial batch of 346 vials using a protocol recommended by the World Health Organization (WHO).

“We produced the vials at MedicusRx, a private pharmacy owned by Anitra MacLaughlin, Pharm.D., and Brent Dance, Pharm.D., who generously donated sterile compounding space in their facility,” MacLaughlin said.

Since the initial batch, the CDC released a slightly different protocol for VTM preparation. The TTUHSC team adopted the protocol, rush-ordered necessary materials and produced two batches of more than 2300 vials.

These vials have passed sterility testing, and on April 3, the state lab in Lubbock

confirmed the quality by running positive controls with COVID-19 samples. The aseptically-batched

VTM vials are now ready for field use.

These vials have passed sterility testing, and on April 3, the state lab in Lubbock

confirmed the quality by running positive controls with COVID-19 samples. The aseptically-batched

VTM vials are now ready for field use.

“From the onset, the VTM production has been a team effort between faculty in the Departments of Pharmaceutical Sciences, Pharmacy Practice and Pediatrics,” MacLaughlin said.

He also applauded the private-public partnership with MedicusRx and TTUHSC.

“I know of several private cleanrooms in Amarillo where additional VTM could be made,” MacLaughlin said. “It’s certainly not as efficient as commercial manufacturers, but this process could be scaled up.”

Along with MacLaughlin, Bickel Conatser and Bell, other team members Constantinos Mikelis, Ph.D, assistant professor, Behnam Noorani, graduate student, Siavash Shahbazi, graduate student, Desmon Dunn, unit manager, Heather Houser, pharmacy technician, Maegan Whitworth, Pharm.D., assistant professor, and Jill Frost, Pharm.D., assistant professor.

Stay up to date on the latest COVID-19 information from TTUHSC on our coronavirus information page.